GatorTrax electric systems exhibit several recurring issues that owners frequently encounter.

These problems range from basic motor malfunctions to complex circuit board failures, affecting both performance and reliability.

Understanding these common electrical complications helps prevent unexpected breakdowns and extends equipment longevity.

While some issues require professional intervention, others can be addressed through proper maintenance and timely troubleshooting.

The following analysis examines these prevalent electrical challenges and their solutions.

Motor Failure and Performance Issues

Motor failure and performance issues in GatorTrax electric systems commonly stem from malfunctioning overspeed control mechanisms, particularly when operating on inclines.

When performance degradation occurs, the electric motor may require removal for detailed diagnostic testing of internal components.

This assessment includes evaluating input and output ratios from the controller to determine whether the issue lies with the motor or control system.

Systems experiencing recurring problems, especially those with motor replacements within the previous two years, often necessitate complete motor replacement.

To prevent motor failure and maintain peak performance, regular maintenance protocols should include thorough inspection of electrical connections.

These preventive measures help identify potential issues before they escalate into significant operational problems, ensuring consistent and reliable performance of the GatorTrax electric system.

Control Switch Malfunctions

Control switch malfunctions represent a significant operational concern for GatorTrax electric systems, often manifesting alongside motor performance issues.

These malfunctions can render vehicles non-responsive, preventing startup and command execution.

Key indicators include intermittent power loss, motor engagement failures, and non-functional electrical components.

Maintaining peak switch performance requires vigilant inspection of connections, as corrosion and loose wiring frequently impair electrical conductivity.

When switches exhibit damage or wear patterns, installing OEM replacement parts guarantees system compatibility and reliable operation.

Effective diagnosis typically involves multimeter testing to verify continuity and proper voltage distribution across the motor and auxiliary systems.

This systematic approach to troubleshooting control switch malfunctions helps restore vehicle functionality and prevents cascading electrical issues that could compromise overall performance.

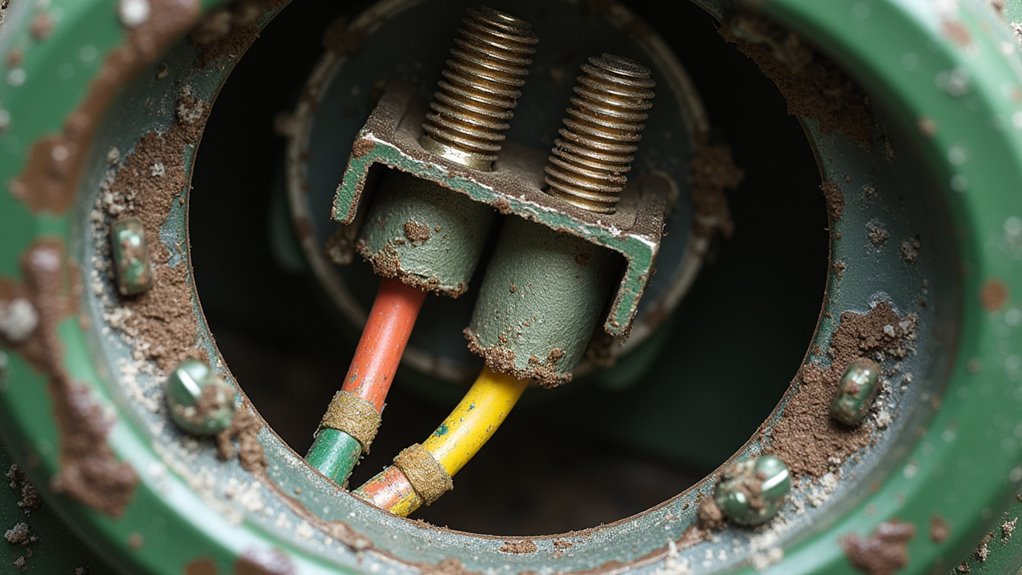

Wiring Connection Problems

Wiring connection problems pose significant challenges for GatorTrax electric systems, often manifesting through various operational failures and intermittent malfunctions.

When components fail to start or electrical displays become non-responsive, a thorough inspection of all connections becomes crucial for proper diagnosis.

Corrosion at connection points frequently impedes electrical flow, necessitating regular maintenance of tight and secure connections.

System reliability depends heavily on maintaining ground integrity and protecting wiring harnesses from exposure or damage that could create shorts.

Technicians employ multimeters to test voltage and continuity at connection points, enabling precise identification of electrical flow issues.

This systematic approach to diagnosing wiring connection problems guarantees that GatorTrax systems maintain peak performance and reliability, preventing costly downtime and component failures.

Battery Drain Concerns

Battery drain issues represent a significant operational challenge in GatorTrax electric systems, often stemming from the same connectivity problems that affect general wiring performance.

These battery drain concerns manifest through faulty connections, corroded terminals, and compromised wiring integrity, all of which impede efficient electrical flow.

Environmental factors, particularly exposure to water and mud, can accelerate battery deterioration through short circuits and corrosion of essential components.

Load testing and regular water level checks are critical diagnostic measures for identifying weak or failing batteries.

Additionally, malfunctioning controllers and electric motors may draw excessive power, exacerbating drain problems.

To address these issues effectively, maintaining clean and secure ground connections is imperative.

This systematic approach to electrical maintenance helps guarantee peak battery performance and extends operational longevity.

Water Damage to Electrical Components

When exposed to water and mud, GatorTrax electrical systems face substantial risks of component degradation and failure.

Water intrusion commonly leads to corrosion of electrical connections, damaged wiring, and malfunctioning displays, particularly affecting starting mechanisms and hour meters.

Vehicle immersion or prolonged exposure to moisture can compromise critical components, including controllers and motors, necessitating replacement with OEM parts.

Users experiencing electrical issues following water exposure often discover loose connections and corroded ground points during inspection.

To maintain system integrity, regular checks of drain tubes and electrical connections are essential, particularly after operating in wet conditions.

Early detection of water damage to electrical components through systematic inspection can prevent more extensive system failures and minimize repair costs.

Sensor and Safety System Glitches

Beyond water damage concerns, sensor and safety system glitches represent a significant operational challenge for GatorTrax electric vehicles.

These malfunctions manifest through erratic performance, including unexpected speed restrictions and motor engagement failures due to misread signals.

| Component | Issue | Solution |

|---|---|---|

| Speed Sensor | False readings | Check voltage/continuity |

| Safety Control | Overspeed activation | Inspect connections |

| Motor Sensor | Engagement failure | Test signal integrity |

| Electronic Unit | Signal misreading | Verify wiring contacts |

Diagnostic procedures require systematic testing with a multimeter to verify proper voltage and continuity across connections.

The integrity of sensor junctions is particularly critical, as corrosion can compromise signal accuracy and trigger false safety system responses.

Regular maintenance should focus on securing connections and protecting against moisture infiltration to prevent sensor-related performance issues.

Power Supply Disruptions

Power supply disruptions represent one of the most critical operational challenges affecting GatorTrax electric vehicles.

Faulty connections within the electrical system can trigger intermittent performance or complete power loss, requiring immediate attention to maintain peak functionality.

Several key factors contribute to these disruptions.

Corroded or loose battery connections compromise power delivery, while malfunctioning controllers affect input-output ratios.

The 15 amp fuse, a common failure point, requires regular inspection and replacement when blown.

To diagnose these issues effectively, technicians employ multimeters to test connections, grounds, and the electric motor, identifying specific areas of power loss.

Implementing preventive measures, such as routine battery connection inspections and systematic diagnostic procedures, helps maintain consistent power supply and guarantees reliable operation of GatorTrax electric systems.

Remote Control System Failures

Understanding remote control system failures in GatorTrax covers requires analysis of multiple potential failure points.

Weak batteries in the remote control unit can impair signal transmission, leading to operational delays and unreliable performance.

Electronic interference from nearby devices and physical obstacles can further disrupt signal communication between the remote and cover system.

To maintain peak functionality, users should implement regular battery checks and replacements.

The system may occasionally require reprogramming, which necessitates following the manufacturer’s specified procedures in the user manual.

Additionally, inspection of wiring connections between the remote control mechanism and the cover’s motor is essential, as corrosion and wear can compromise system reliability.

These preventive measures help guarantee consistent remote control operation and minimize disruptions to the cover’s automated functions.

Canister Mechanism Electrical Issues

The GatorTrax canister mechanism’s electrical system presents several potential failure points that require systematic diagnosis and maintenance.

When experiencing operational issues, owners should first inspect the electric motor, which can exhibit slow performance or complete failure due to internal component deterioration.

Regular inspection of electrical connections within the canister assembly is essential for preventing corrosion-related malfunctions.

| Component | Common Issue | Solution |

|---|---|---|

| Motor | Slow operation | Check internal components |

| Controller | Signal ratio problems | Verify input/output settings |

| Solenoid | Power delivery issues | Replace if faulty |

For intermittent retraction problems, troubleshooting should focus on the controller’s input/output ratios and proper fuse specifications.

Maintenance protocols should include regular cleaning of electrical connections and verification of component tightness to guarantee ideal canister performance and longevity.

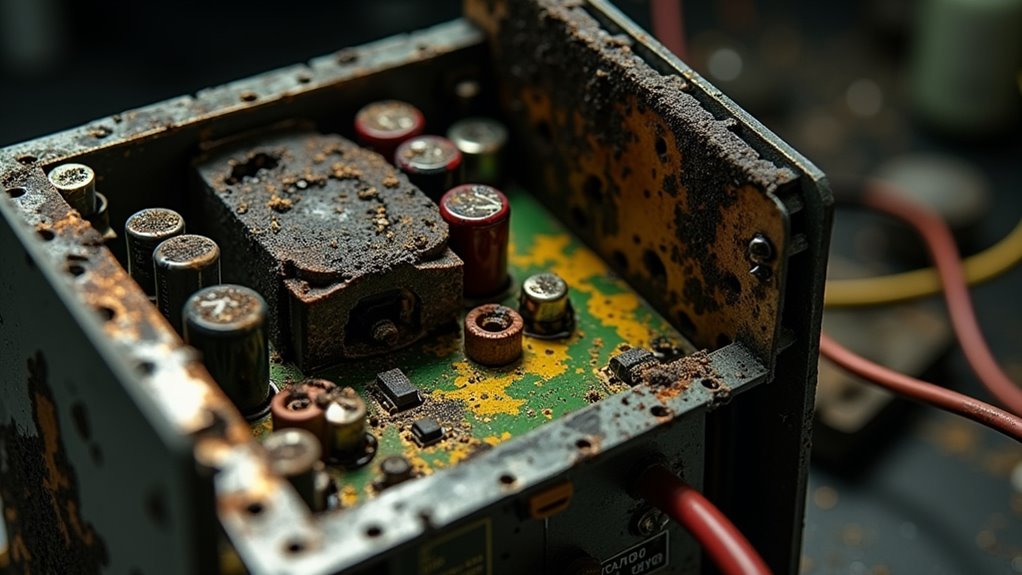

Circuit Board and Fuse Problems

When diagnosing GatorTrax electrical malfunctions, circuit board and fuse problems represent critical areas requiring systematic evaluation.

Circuit board issues commonly manifest through non-functional displays and starting problems, necessitating thorough testing with a multimeter for accurate diagnosis.

The 15 amp fuse serves as a critical component, and its failure can result in complete electrical system shutdown.

Visual inspection of fuse condition and proper replacement are essential steps in restoring system functionality.

Additionally, corrosion at connection points and loose wiring, particularly around the fuel shut-off solenoid, can create intermittent electrical failures.

Regular inspection of wire integrity and terminal cleanliness prevents system deterioration.

Maintaining clean connections and addressing electrical problems promptly guarantees peak performance and extends the operational life of GatorTrax electrical systems.

FAQs

What Is the Best Retractable Tonneau Cover for F150?

The BAKFlip MX4 offers ideal tonneau benefits for F150 owners, combining superior durability, weather resistance, and full bed accessibility. Its robust aluminum construction and low-profile design deliver exceptional performance in diverse conditions.

Are Gator Tonneau Covers Made in the USA?

Yes, Gator Tonneau Covers exemplify American manufacturing excellence, with production based in their Wisconsin facility. The company maintains domestic material sourcing and manufacturing operations, supporting U.S. jobs and quality control standards.

Final Thoughts

Regular inspection, proper maintenance, and prompt repairs remain essential for addressing GatorTrax electrical problems.

Systematic diagnostics detect motor failures, control switch malfunctions, and wiring issues before they escalate.

Professional servicing guarantees peak performance, extends equipment longevity, and prevents costly breakdowns.

Understanding these common electrical issues enables operators to implement preventive measures, maintain system integrity, and maximize operational efficiency.