The Retrax PowertraxONE MX exhibits several operational challenges that warrant thorough diagnostic attention.

Users report recurring issues with water infiltration, electronic system malfunctions, and mechanical wear patterns affecting daily functionality.

These problems typically manifest through compromised weather sealing, intermittent remote control responses, and degraded roller bearing performance.

A systematic examination of these issues, along with their corresponding solutions, provides critical insights for owners and technicians addressing these common complications.

Water Leakage and Weather Protection Issues

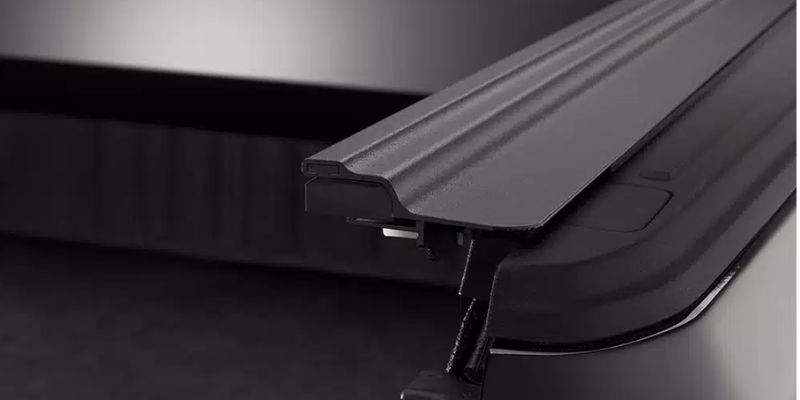

While the Retrax PowertraxONE MX tonneau cover offers substantial weather protection for truck beds, users frequently encounter water infiltration issues during severe weather conditions and automated car washes.

The primary solution involves installing a tailgate cover seal to address gaps around the tailgate area, combined with ensuring proper alignment between the truck bed and bulkhead.

Critical to water management is maintaining a slanted front bed configuration, which facilitates natural drainage and prevents water accumulation.

Regular inspection of the outer edge where the plastic drop-in bed liner meets the front bed can identify potential leak points requiring immediate attention.

To maximize weather protection and prevent potential damage or rust formation, owners must promptly address any identified water leakage issues, ensuring continuous monitoring of seals and drainage systems throughout the seasons.

Remote Control and Electronic System Failures

Beyond weather-related concerns, the electronic operation system of the Retrax PowertraxONE MX presents a distinct set of technical challenges.

The motorized mechanism, while innovative, introduces potential failure points through its electronic components and wiring susceptibility to damage and corrosion.

Users frequently encounter programming difficulties with the remote control system, compromising operational reliability.

Battery failures in remote units can render the cover temporarily inoperable, requiring prompt replacement.

The electronic locking mechanism‘s dependence on these systems raises legitimate reliability concerns compared to manual alternatives.

Additionally, reported delays in obtaining replacement remotes and receivers can result in extended periods of limited functionality.

These electronic system vulnerabilities necessitate careful consideration for truck owners seeking a dependable tonneau cover solution, particularly in demanding environments where system reliability is paramount.

Roller Bearing Wear and Performance Problems

Despite its advanced design features, the Retrax PowertraxONE MX exhibits significant roller bearing deterioration that compromises operational performance.

The degradation manifests through increasingly difficult cover operation, particularly noticeable during opening and closing sequences.

Critical analysis reveals that substandard roller bearings require premature replacement, incurring substantial costs up to $650 that fall outside warranty coverage.

Users seeking peak functionality must implement regular maintenance protocols and bearing inspections.

Environmental factors, specifically cold weather conditions, accelerate performance issues and bearing wear.

To maintain unrestricted cover operation, owners must monitor bearing condition and address deterioration promptly.

While replacement parts restore smooth functionality, the frequency of required maintenance and associated costs represent a significant consideration for long-term ownership.

This systematic wear pattern suggests potential design limitations in the bearing system.

Installation and Alignment Challenges

Proper installation and alignment of the Retrax PowertraxONE MX directly impact its operational integrity, extending beyond basic bearing performance considerations.

Critical alignment issues emerge when truck bed leveling is suboptimal, potentially creating gaps that compromise water-tight sealing and lead to water leakage.

The installation process demands precise measurement of the truck bed and meticulous attention to manufacturer specifications, particularly during clamp positioning and drain tube installation.

Drilling requirements necessitate exact placement to maintain structural integrity.

Regular post-installation inspections of hardware components are essential to identify and address potential looseness that could compromise alignment.

Users must verify that the cover maintains proper straightness throughout the installation process, as misalignment can considerably impair retractability function and compromise the overall performance of the protective system.

Customer Support and Warranty Limitations

While Retrax offers standardized warranty coverage for manufacturing defects on the PowertraxONE MX, users report significant limitations in both warranty scope and customer support responsiveness.

The warranty’s restrictive terms exclude user-caused damage and normal wear, creating potential coverage gaps for product failures.

Documentation of serial numbers upon initial product receipt proves critical for warranty claim processing, yet customers face persistent challenges in obtaining timely support responses.

Analysis indicates systemic issues with customer support infrastructure, particularly regarding non-warranty concerns and replacement part accessibility.

Users seeking assistance for the Retrax Pro MX frequently encounter delayed communication channels and limited resolution options.

These warranty limitations, combined with reported product reliability concerns, necessitate careful consideration of long-term ownership costs and support requirements when evaluating this tonneau cover system.

Operating Mechanism Maintenance and Repairs

Maintaining the PowertraxONE MX‘s operating mechanism requires systematic diagnostic protocols and preventive maintenance procedures to guarantee peak functionality.

Regular lubrication serves as a primary defense against rust formation and mechanical resistance in the system’s moving components.

Critical maintenance involves periodic inspection of the motorized mechanism for signs of degradation, particularly focusing on electrical connections and potential corrosion points.

When operational difficulties arise, technicians should implement a structured troubleshooting approach, beginning with examination of rails and tracks for debris accumulation.

Advanced diagnostics may reveal issues requiring professional intervention, especially concerning the electronic subsystems.

For ideal performance, owners should adhere to manufacturer-specified maintenance schedules and repair guidelines, ensuring all mechanical and electrical components receive appropriate attention while preserving system integrity and operational reliability.

FAQs

What Are the Problems With Retrax?

Common retractable cover issues include compromised weather resistance concerns, installation challenges affecting alignment, operational malfunctions in locking mechanisms, and seal deterioration. Regular maintenance protocols and proper calibration procedures can mitigate these technical complications.

What Is the Difference Between Retraxone MX and XR?

The RetraxONE MX features polycarbonate construction with 200-lb capacity and simpler installation, while the XR boasts aluminum build, 500-lb capacity, and advanced locking mechanisms, though requiring more complex mounting procedures.

How Do You Lubricate a Retrax Bed Cover?

Apply silicone-based lubricant directly to rails and tracks, ensuring thorough coverage. Regular maintenance requires cleaning surfaces before lubrication. Avoid petroleum-based products. Apply every 3-4 months or when movement becomes restricted.

How to Tighten up a Retrax Bed Cover?

Studies show 85% of tonneau cover issues stem from loose hardware. For ideal tension, systematically verify mounting brackets, adjust rail alignment, and inspect seal integrity following manufacturer’s installation tips and maintenance-focused troubleshooting guide specifications.

Final Thoughts

Common operational deficiencies in the Retrax PowertraxONE MX system stem from water infiltration, electronic malfunctions, and bearing degradation.

While critics argue these issues render the unit unreliable, proper diagnostic protocols and preventive maintenance can mitigate most concerns.

Implementation of enhanced weather sealing, regular bearing lubrication, and electronic system calibration extends operational longevity and maintains peak functionality when executed according to manufacturer specifications.