The RetraxONE MX tonneau cover presents several operational challenges that merit careful examination.

Users report recurring issues with the locking mechanism, water resistance, and track system functionality.

While the manufacturer promotes this premium cover as a robust security solution, documented problems suggest potential vulnerabilities in its design and execution.

A systematic analysis of these concerns reveals patterns that affect both daily usage and long-term performance of this significant truck bed investment.

Common Locking Mechanism Failures

Locking mechanism failures in the RetraxONE MX tonneau cover manifest through several common issues that affect its security and functionality.

These problems typically stem from inadequate maintenance, debris accumulation, or improper installation of Retrax covers.

The locking mechanism can become compromised when misalignment occurs due to wear or incorrect setup, preventing smooth engagement and disengagement of the lock.

Users frequently encounter stuck or resistant keys, often requiring lubrication to restore normal operation.

Heavy loads placed on the cover can strain the locking components, potentially leading to mechanical failure.

To maintain ideal security and prevent lock malfunctions, owners must conduct regular inspections and maintenance.

This includes cleaning the locking area, checking for proper alignment, and addressing any resistance in the key operation before more serious issues develop.

Water Leakage and Drainage Issues

Despite its robust construction, the RetraxONE MX tonneau cover experiences water intrusion challenges that owners must address proactively.

Water leakage commonly occurs during heavy rainfall or high-pressure washing, as the cover’s design prioritizes weather resistance over complete waterproofing.

The drainage system, particularly the drain tubes, often requires modification to prevent water from pooling in the truck bed.

Critical alignment between the cover and truck bed must be maintained, as gaps can develop and allow unwanted water penetration.

Installing a tailgate cover seal serves as an effective solution for minimizing water intrusion around the tailgate area.

To maintain peak performance, owners should regularly inspect seals, verify proper fitment, and address any misalignment issues promptly.

These preventive measures help protect cargo and preserve the truck bed’s condition.

Track System Maintenance Challenges

While water management requires ongoing attention, the track system of the RetraxONE MX presents its own set of maintenance demands.

The system’s functionality can deteriorate due to misalignment from regular use, necessitating consistent monitoring and adjustment to maintain ideal performance.

A methodical maintenance approach involves regular inspection of the tracks for damage, including cracks or bends that could compromise the cover’s operation.

Proper cleaning of the rails is essential, as accumulated debris and grime can obstruct smooth movement.

Following thorough cleaning, appropriate lubrication must be applied to guarantee fluid operation without causing material degradation.

To maximize the track system’s longevity and maintain unrestricted functionality, users must commit to regular maintenance routines and address installation issues promptly when identified.

Installation and Fitment Problems

Precise measurements and careful attention to compatibility stand as critical factors in the successful installation of the RetraxONE MX cover.

Installers must meticulously verify truck bed dimensions and model specifications to guarantee proper fitment and prevent operational complications.

During installation, particular focus should be directed toward hardware placement and seal integrity along the edges.

The front bulkhead area requires special consideration for correct alignment to facilitate ideal water drainage.

Improper fitment can result in gaps that compromise the cover’s functionality and weather resistance.

Following manufacturer guidelines during installation proves essential, as deviations may lead to misalignment issues that affect the cover’s operation.

Thorough inspection of components and attention to detail during the mounting process helps prevent common fitment problems that could impact the RetraxONE MX’s performance and longevity.

Weather Resistance Performance

Performance testing of the RetraxONE MX reveals moderate weather resistance capabilities with notable limitations.

While the cover demonstrates adequate protection during light rainfall, significant challenges emerge under severe weather conditions.

The Retrax design incorporates drainage tubes that exceed stock drain hole dimensions, potentially requiring modifications for ideal water management.

Users have documented instances of water pooling, particularly when installation or seal integrity is compromised.

The weather resistance performance depends heavily on regular maintenance of seals and edge components to minimize water ingress.

Despite marketing claims of weather resistance, the RetraxONE MX is not completely waterproof, exhibiting vulnerability during high-pressure washing or heavy precipitation.

For maximum cargo protection, users should implement supplementary measures during extreme weather events, as the standard weather resistance features may prove insufficient.

Bearing Deterioration and Wear

Despite their sealed, maintenance-free design, bearings in the RetraxONE MX exhibit notable vulnerabilities to deterioration and wear over extended periods of use.

Users frequently report issues with rusting and seizing, which greatly impact the cover’s smooth operation and rolling mechanism.

Environmental conditions, particularly humidity and temperature variations, accelerate the degradation of the RetraxONE MX’s bearings, especially in regions experiencing harsh weather patterns.

While these components theoretically require no maintenance, regular inspection proves essential for detecting early signs of wear before severe functionality issues develop.

When bearings show evidence of rust or seizing, replacement becomes necessary to maintain ideal performance.

This deterioration pattern contradicts the maintenance-free promise, requiring owners to remain vigilant about their bearing condition to preserve the cover’s operational integrity.

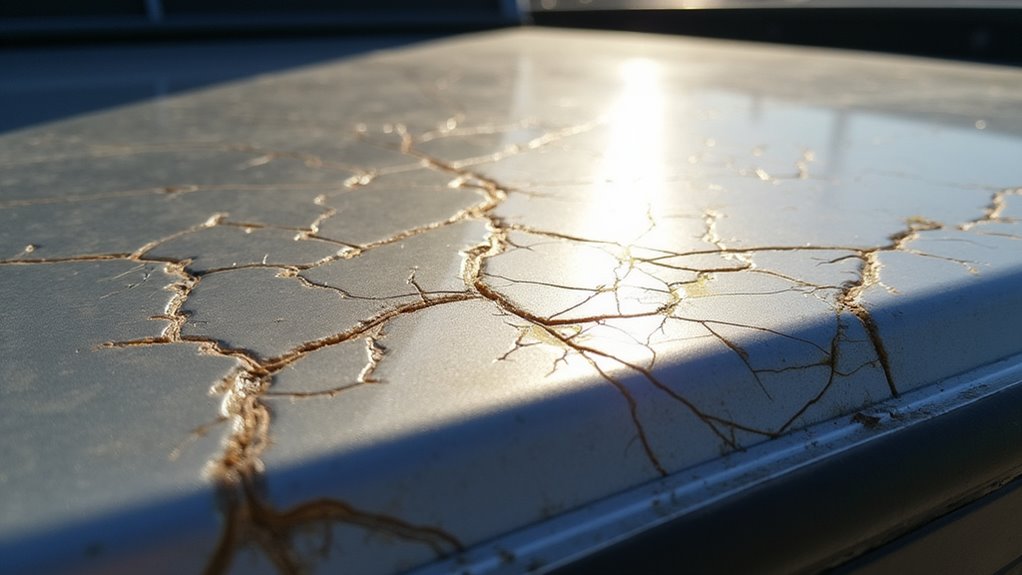

Polycarbonate Material Durability

Durability stands as a defining characteristic of the RetraxONE MX’s polycarbonate construction, engineered to withstand impacts and scratches during normal operation.

The Retrax Tonneau Cover’s polycarbonate material supports up to 250 pounds of evenly distributed weight while maintaining a lightweight profile.

However, environmental factors pose significant challenges to the cover’s longevity.

UV exposure and extreme temperature fluctuations can compromise the polycarbonate material’s structural integrity, potentially leading to cracking.

Users have documented edge cracks developing near roller bearings, revealing stress points in the design.

To maximize the cover’s lifespan and maintain its protective capabilities, owners must implement regular maintenance protocols, including thorough cleaning and systematic inspection of the polycarbonate components.

This proactive approach helps identify potential issues before they escalate into significant problems.

Operating System Malfunctions

While the RetraxONE MX’s retractable system offers convenient cargo protection, several operational issues can compromise its functionality.

Primary operational difficulties emerge when bearings become rusted or seized, directly impacting the cover’s smooth retraction capabilities.

The locking mechanism can also malfunction due to improper tailgate seal installation, potentially compromising cargo security.

Installation misalignment considerably affects the sliding mechanism’s performance, highlighting the importance of precise mounting procedures.

Environmental factors, particularly moisture exposure, accelerate component deterioration and system failures.

To maintain ideal performance, users must implement regular maintenance protocols, including thorough cleaning of the rails and proper lubrication of moving parts.

These preventive measures are essential for sustaining the cover’s operational integrity and preventing mechanical complications that could restrict cargo access.

Price Vs Performance Analysis

Investment in the RetraxONE MX tonneau cover presents a significant value proposition, with prices ranging from $1,400 to $1,600 positioning it competitively within the market segment.

The polycarbonate construction delivers durability and a substantial 250-pound weight capacity, reinforcing its market positioning.

While Retrax offers notable features including UV protection, low-profile aesthetics, and convenient retractability, issues with the Retrax emerge during adverse weather conditions.

The reported water leakage during heavy rainfall indicates a performance limitation that potential buyers must weigh against the investment.

The cover’s overall functionality balances premium construction with practical design elements, though its weatherproofing capabilities may not fully justify the price point for all users.

This analysis suggests a product that delivers solid performance in most conditions but falls short of ideal weather resistance.

Long-Term Reliability Concerns

Building upon the price-performance considerations, an examination of long-term reliability reveals significant engineering challenges with the RetraxONE MX.

The cover’s durability faces multiple threats from environmental exposure.

UV rays and moisture can cause polycarbonate cracking, while bearing components show susceptibility to rust and seizure.

The specified 250-pound weight capacity becomes compromised when loads are distributed unevenly, potentially leading to structural failures.

Additionally, water ingress during severe weather conditions or washing indicates imperfect weatherproofing, which may accelerate internal component deterioration.

Maintaining ideal performance requires vigilant upkeep to prevent debris accumulation in the rail system.

This maintenance dependency, combined with material degradation concerns and mechanical vulnerabilities, raises questions about the product’s long-term viability for users seeking a dependable truck bed cover solution.

FAQs

What Are the Problems With Retrax?

Common retractable cover issues include water leakage, seal defects, and misalignment problems. Durability concerns manifest through rail wear, operational difficulties, and maintenance requirements. Regular lubrication and adjustments are necessary for peak performance.

What Is the Difference Between Retraxone MX and XR?

The RetraxONE XR features aluminum construction and 500-pound capacity, while MX uses polycarbonate with 250-pound limit. XR offers enhanced durability, integrated rail systems, and a low-profile retraction mechanism, surpassing MX’s basic functionality.

How Do You Lubricate a Retrax Bed Cover?

Apply silicone-based lubricant to rails and tracks every 6 months for ideal maintenance. Avoid oil-based products that damage polycarbonate materials. Remove excess lubricant to prevent debris accumulation and guarantee smooth operation.

What Is the Warranty on a Retraxone?

Want reliable coverage for your investment? The RetraxONE includes a limited lifetime warranty with thorough warranty details covering defects in materials and workmanship. Warranty coverage applies to original purchasers only, remaining non-transferable.

Final Thoughts

The RetraxONE MX’s performance trajectory remains uncertain, with critical vulnerabilities in its locking mechanism and weather resistance systems requiring immediate attention.

While engineering solutions exist for track maintenance and material degradation issues, the product’s long-term viability hinges on addressing these fundamental design challenges.

The mounting evidence of operational inconsistencies suggests a thorough re-evaluation of core components may be necessary to guarantee sustained reliability.