Ever found yourself scratching your head, wondering about all those mysterious parts that make up your tonneau cover?

Well, you’re in luck! I’m about to take you on a wild ride through the world of tonneau cover components.

Whether you’re a DIY expert looking to fix your cover or just a curious truck owner, this guide is packed with all the juicy details you’ve been searching for.

So buckle up, and let’s dive into the nuts and bolts (quite literally) of tonneau covers!

Types of Tonneau Covers and Their Parts

Tonneau covers come in various types, each designed to meet different needs and preferences.

In this section, we’ll explore the different types of tonneau covers and break down their components.

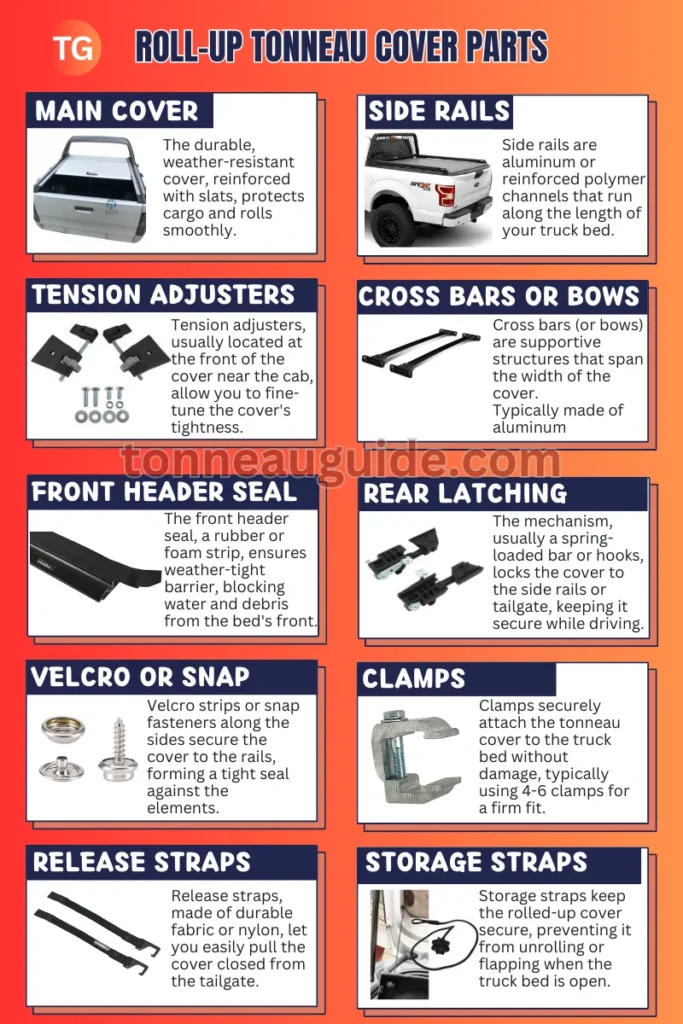

1. Roll-Up Tonneau Cover Parts

Roll-up tonneau covers are popular for their versatility and ease of use. They’re ideal for truck owners who need frequent access to their entire truck bed.

Main Cover

The main cover is the primary component, typically made from heavy-duty vinyl or durable fabric like canvas.

This material is engineered to be weather-resistant, protecting your cargo from rain, snow, and harmful UV rays.

The cover is reinforced with horizontal slats or bars that provide structure and allow for smooth rolling.

Side Rails

Side rails are aluminum or reinforced polymer channels that run along the length of your truck bed. They serve multiple purposes:

- Guide the cover as it rolls up and down

- Provide a secure mounting point for the cover

- Create a water-tight seal along the sides of the bed

Most side rails use a clamp system for installation, eliminating the need for drilling into your truck bed.

Tension Adjusters

Tension adjusters, usually located at the front of the cover near the cab, allow you to fine-tune the cover’s tightness.

Proper tension prevents sagging and flapping at high speeds while ensuring easy operation.

Cross Bars or Bows

Cross bars (or bows) are supportive structures that span the width of the cover. Typically made of aluminum, they serve to:

- Prevent water pooling by maintaining a slight arch in the cover

- Provide additional support for the fabric or vinyl

- Help the cover maintain its shape when closed

Front Header Seal

The front header seal is a rubber or foam strip that runs along the front of the cover, just behind the cab.

It creates a weather-tight seal, preventing water and debris from entering at the front of the bed.

Rear Latching Mechanism

This mechanism secures the cover at the tailgate end. It typically consists of a spring-loaded bar or a series of hooks that engage with the side rails or tailgate, ensuring the cover remains closed and secure while driving.

Velcro or Snap Fasteners

Along the sides of the cover, you’ll find either Velcro strips or snap fasteners. These secure the edges of the cover to the side rails, creating a tight seal against the elements.

Clamps

Clamps attach the tonneau cover system to your truck bed. They’re designed to grip the bed rails securely without causing damage.

Most systems use 4-6 clamps for a secure fit.

Release Straps

Release straps are durable fabric or nylon straps attached to the rear of the cover. They allow you to easily pull the cover closed from the tailgate end of the truck.

Storage Straps

Storage straps secure the cover when it’s fully rolled up, preventing it from unrolling or flapping in the wind when you need your entire truck bed open.

2. Folding Tonneau Cover Parts

Folding tonneau covers offer a balance of security and accessibility. They consist of several rigid panels that fold up accordion-style.

Folding Panels

The folding panels are the main component, typically made from aluminum, fiberglass, or hard plastic.

These panels provide excellent security and weather protection. Most folding covers have 3-4 panels.

Hinges

High-quality hinges connect the folding panels.

These hinges are engineered to withstand thousands of open/close cycles and often incorporate weather sealing to prevent leaks at junction points.

Seals Between Panels

Rubber or foam seals run between each panel. When the cover is closed, these seals compress to create a water-tight barrier, preventing leaks at the panel junctions.

Front and Rear Seals

Similar to roll-up covers, folding covers have seals at the front (near the cab) and rear (at the tailgate) of the truck bed.

These are typically bulkier than those on roll-up covers to accommodate the rigid panels.

Latching Mechanisms

Folding covers usually have a primary latch at the tailgate end and may have additional latches between panels for extra security.

These latches are often spring-loaded for easy operation.

Clamps

Like roll-up covers, folding covers use clamps to attach to the truck bed. These may be heavier-duty to support the weight of the rigid panels.

Safety Straps

When the cover is folded open, safety straps secure it in place. This prevents damage from the cover slamming against the cab in windy conditions or during travel.

Drain Tubes

Many folding covers incorporate a drainage system. Small tubes channel any water that might seep past the seals out of the truck bed, keeping your cargo dry.

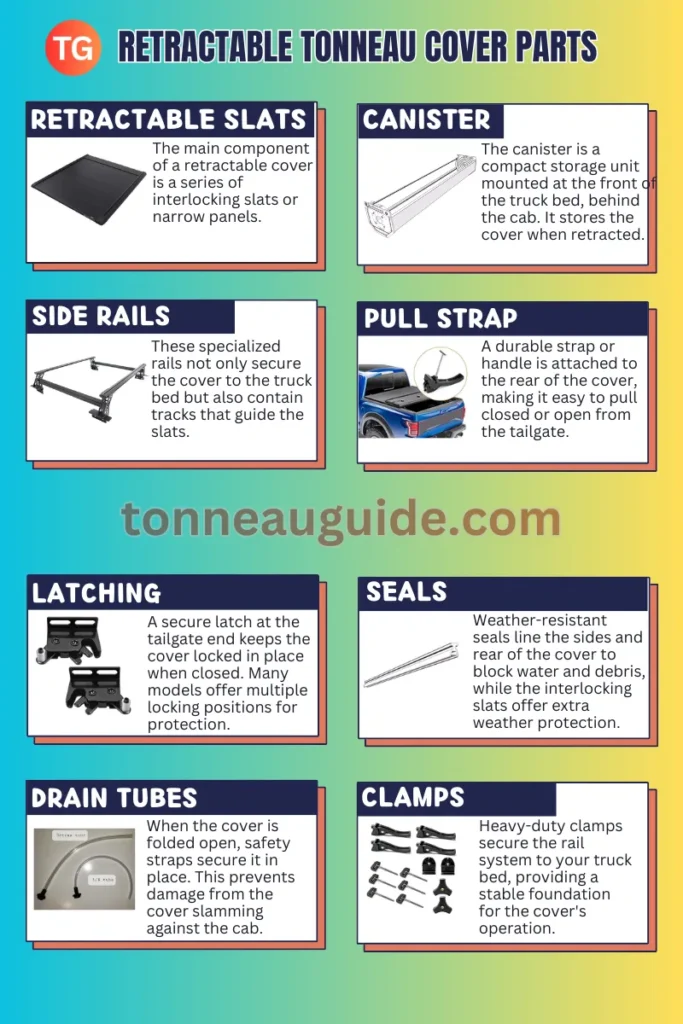

3. Retractable Tonneau Cover Parts

Retractable tonneau covers offer a sleek, low-profile look and easy operation. They roll into a canister at the front of the truck bed.

Retractable Slats or Panels

The main component of a retractable cover is a series of interlocking slats or narrow panels.

These are typically made of aluminum or strong polymers and are designed to slide smoothly along the side rails.

Canister

The canister is a compact storage unit mounted at the front of the truck bed, just behind the cab.

It houses the cover when retracted, protecting it from the elements and keeping it out of the way.

Side Rails with Built-in Tracks

These specialized rails not only secure the cover to the truck bed but also contain tracks that guide the slats or panels as they retract and extend.

Pull Strap or Handle

A durable strap or handle is attached to the rear of the cover, allowing you to easily pull the cover closed or open it from the tailgate end of the truck.

Latching Mechanism

A secure latch at the tailgate end keeps the cover locked in place when closed. Many models offer multiple locking positions for versatile cargo protection.

Seals

Weather-resistant seals run along the sides and rear of the cover to keep out water and debris. The interlocking design of the slats often provides additional weather protection.

Drain Tubes

Like folding covers, many retractable models include a drainage system to channel away any water that might seep in, protecting your cargo from moisture.

Clamps

Heavy-duty clamps secure the rail system to your truck bed, providing a stable foundation for the cover’s operation.

4. Snap-On Tonneau Cover Parts

Snap-on covers are a more traditional, economical option. They’re lightweight and easy to remove entirely when needed.

Main Cover

The main cover is typically made from vinyl or canvas. It’s a single piece designed to stretch taut over the truck bed.

Snap Fasteners

These are the defining feature of snap-on covers. Male snap components are installed along the truck bed rails, while female snaps are sewn into the cover. They snap together to secure the cover in place.

Support Bows or Rods

Rigid support bars, often made of aluminum, span the width of the cover. They prevent sagging and help shed water and debris.

Corner Brackets

These small but crucial components help secure the support bows in place, maintaining the cover’s shape and tension.

Tension Adjusters

Similar to those on roll-up covers, these allow you to fine-tune the cover’s tightness for a smooth, taut fit.

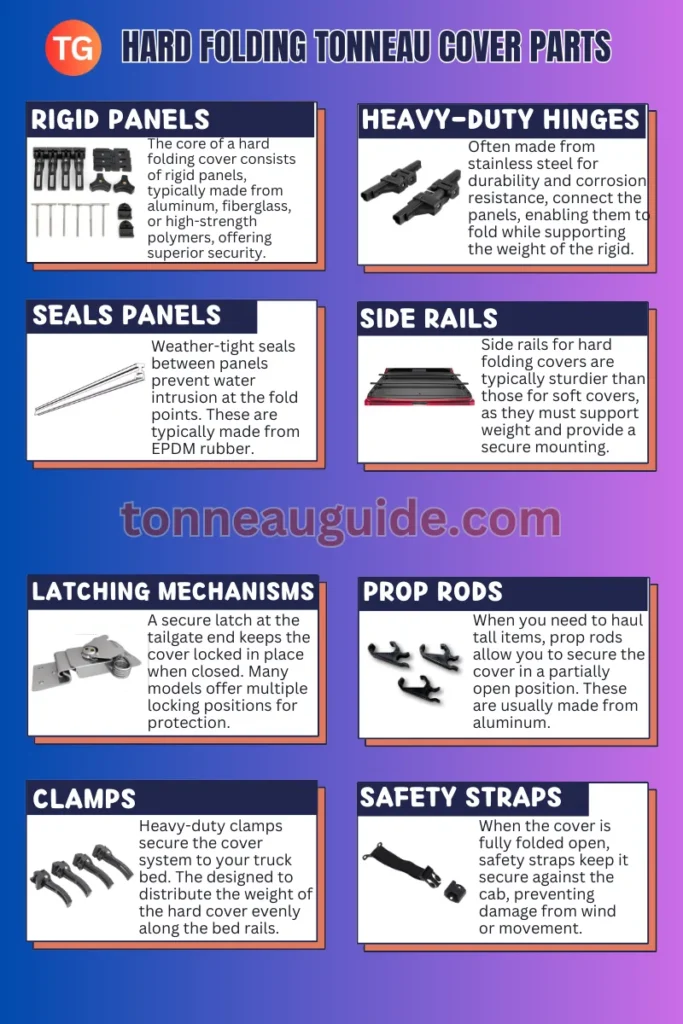

5. Hard Folding Tonneau Cover Parts

Hard covers offer superior security and durability compared to soft covers, while still providing the flexibility to access your full truck bed when needed.

Rigid Folding Panels

The core of a hard folding cover is its rigid panels, usually made from aluminum, fiberglass, or high-strength polymers. These provide excellent security and weather resistance.

Heavy-Duty Hinges

Robust hinges connect the panels, allowing them to fold while supporting the weight of the rigid materials.

These are often made from stainless steel for durability and corrosion resistance.

Seals Between Panels

Weather-tight seals between panels prevent water intrusion at the fold points. These are typically made from EPDM rubber or similar weather-resistant materials.

Side Rails

Side rails for hard folding covers are usually more substantial than those for soft covers, as they need to support more weight and provide a secure mounting point for the folding mechanism.

Latching Mechanisms

These covers typically feature a primary latch at the tailgate end and may have additional locks between panels for enhanced security. Many use slam-latch designs for easy operation.

Prop Rods

When you need to haul tall items, prop rods allow you to secure the cover in a partially open position.

These are usually made from aluminum or steel for strength.

Clamps

Heavy-duty clamps secure the cover system to your truck bed. These are designed to distribute the weight of the hard cover evenly along the bed rails.

Safety Straps

When the cover is fully folded open, safety straps keep it secure against the cab, preventing damage from wind or movement.

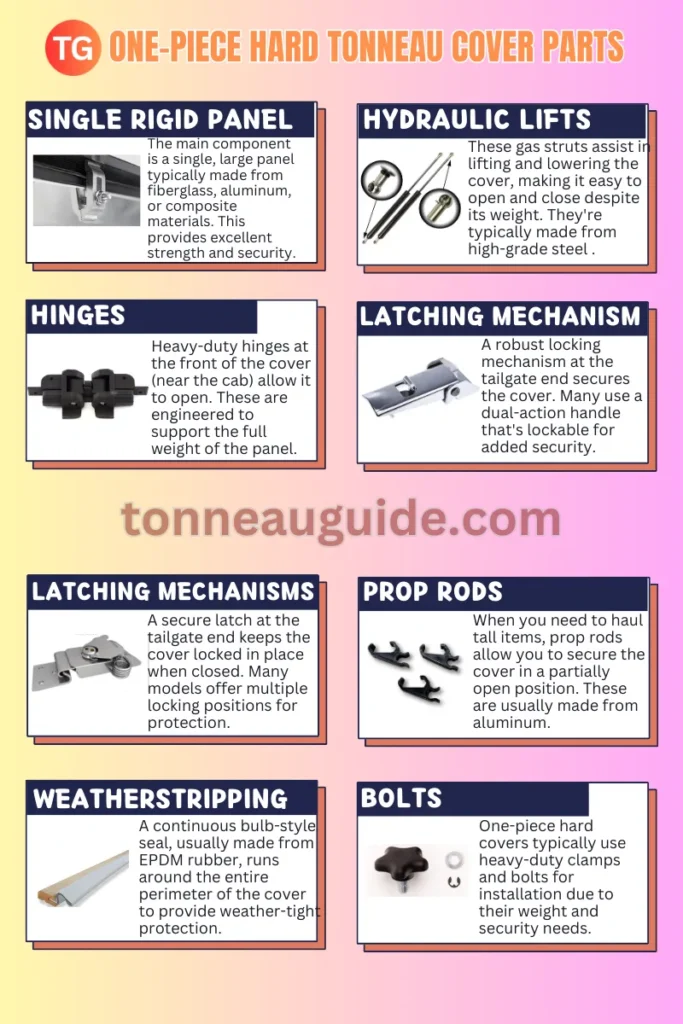

6. One-Piece Hard Tonneau Cover Parts

One-piece hard tonneau covers offer maximum security and a sleek, integrated look.

They’re ideal for those who prioritize cargo protection and don’t need frequent full-bed access.

Single Rigid Panel

The main component is a single, large panel typically made from fiberglass, aluminum, or composite materials. This provides excellent strength and security.

Gas Struts or Hydraulic Lifts

These assist in lifting and lowering the cover, making it easy to open and close despite its weight. They’re usually made from high-grade steel with gas-filled chambers.

Hinges

Heavy-duty hinges at the front of the cover (near the cab) allow it to open. These are engineered to support the full weight of the panel and withstand years of use.

Latching Mechanism

A robust locking mechanism at the tailgate end secures the cover. Many use a dual-action handle that’s lockable for added security.

Weatherstripping

A continuous seal around the entire perimeter of the cover ensures weather-tight protection for your cargo. This is typically a bulb-style seal made from EPDM rubber or similar materials.

Clamps or Bolts

Due to the weight and security requirements of one-piece hard covers, they often use a combination of heavy-duty clamps and bolts for installation.

Some may require minor drilling for the most secure fit.

Understanding these components will help you choose the right tonneau cover for your needs and maintain it properly for years of reliable service.

Comparative Table of Tonneau Cover Types and Their Parts

| Cover Type | Main Components | Unique Features | Ease of Use | Security Level |

|---|---|---|---|---|

| Roll-Up | Fabric/vinyl cover, side rails, cross bars | Completely removable | High | Moderate |

| Folding | Hard panels, hinges, seals | Partial bed access without full removal | High | High |

| Retractable | Slats/panels, canister, tracks | Smooth operation, any-point access | Very High | Very High |

| Snap-On | Fabric cover, snaps, support bows | Low cost, simple design | Moderate | Low |

| Hard Folding | Rigid panels, heavy-duty hinges | Combines security with flexibility | High | Very High |

| One-Piece Hard | Single panel, gas struts | Maximum security and weather protection | Moderate | Extremely High |

Maintenance Tips for Your Tonneau Cover Parts

Now that you’re a tonneau cover parts expert, let’s talk about keeping all these components in tip-top shape:

Regular Cleaning: Give your cover a good wash with mild soap and water. It’s like a spa day for your tonneau!

Lubrication: Keep those moving parts happy with a bit of silicone spray. Focus on hinges, latches, and sliding components.

Tightening: Check all bolts, clamps, and fasteners regularly. Loose parts can lead to a noisy ride or even damage.

Seal Inspection: Give your weatherstripping and seals a once-over now and then. If they’re cracked or worn, it’s time for a replacement.

Tension Adjustment: For fabric covers, make sure the tension is just right. Too loose, and you’ll get flapping; too tight, and you might strain the fabric.

Winter Care: In snowy areas, clear off any heavy snow accumulation. Your cover is tough, but it’s not a snow plow!

UV Protection: For fabric covers, consider using a UV protectant spray. It’s like sunscreen for your tonneau!

Troubleshooting Common Issues

Even the best tonneau covers can have hiccups. Here are some common issues and quick fixes:

Water Leaks: Check your seals and make sure your cover is properly tensioned.

Difficult to Open/Close: Lubricate moving parts and check for any misalignments.

Sagging Fabric: Adjust the tension or check for damaged support bows.

Rattling Noise: Tighten all fasteners and check for any loose components.

Stuck Retractable Cover: Clear any debris from the tracks and ensure the slats aren’t damaged.

Final Thoughts

Whew! We’ve been through quite a journey, haven’t we? From roll-ups to one-piece hardcovers, we’ve unraveled the mystery of tonneau cover parts.

Remember, understanding your cover’s components isn’t just about being a truck know-it-all (though that’s pretty cool too).

It’s about taking better care of your investment, troubleshooting issues like a pro, and getting the most out of your tonneau cover.

So the next time you’re out there cruising with your perfectly maintained cover, give yourself a pat on the back. You’re not just a truck owner – you’re a tonneau cover guru!

I have an older hard folding cover from bison. The side rail rubbers are rotting away. I love the cover and would like to fix it . Possible?